More than 100 years after Upton Sinclair wrote The Jungle, a nascent food-production revolution is taking place in the very same neighborhood where the Chicago Stockyards once dominated the landscape. Vertical farming-the cultivation of crops in vertical, typically indoor, spaces such as urban buildings and skyscrapers-is seen by many as a new frontier in food production, allowing the otherwise unused urban spaces to provide fresh-grown produce for the local community and businesses.

In 2009, IIT Industrial Technology and Management faculty member Blake Davis began an Interprofessional Projects (IPRO) Program course in which students were assigned to plan a vertical farm for the Chicago Sustainable Manufacturing Center, a new endeavor founded by John Edel. The students first tested a few prototype farm beds and then developed a formal plan for the farm after Edel succeeded in securing a 93,000-square-foot former meatpacking plant previously owned by Peer Foods in the Back of the Yards neighborhood. Over the course of several semesters, the IPRO students tested and implemented several components of Edel’s project-known simply as The Plant-including an aquaponic farm that combines raising tilapia with the cultivation of hydroponic crops, creating complementary systems in which the waste produced by the fish provides fertilizer for the crops, which in turn clean the water in which the fish live.

This concept of using complementary systems to eliminate waste is writ large throughout The Plant, which is in the process of becoming a fully self-sufficient, zero-waste food-production and educational facility. Each component of The Plant, from the bakery and beer brewery opening in 2012 to the community kitchens planned for 2013, will either reuse organic waste from other components, such as spent grain from the brewery to feed the tilapia, or provide fuel for the anaerobic digester, which converts organic waste into gas used to heat and power the building.

The students continue to expand the farm and test the existing components, adding mushroom farming in fall 2011, experimenting with growing systems, and exploring the possibility of growing algae for medical use in the tilapia farm. Many students have continued to volunteer and work at The Plant well beyond the involvement required for their IPRO projects.

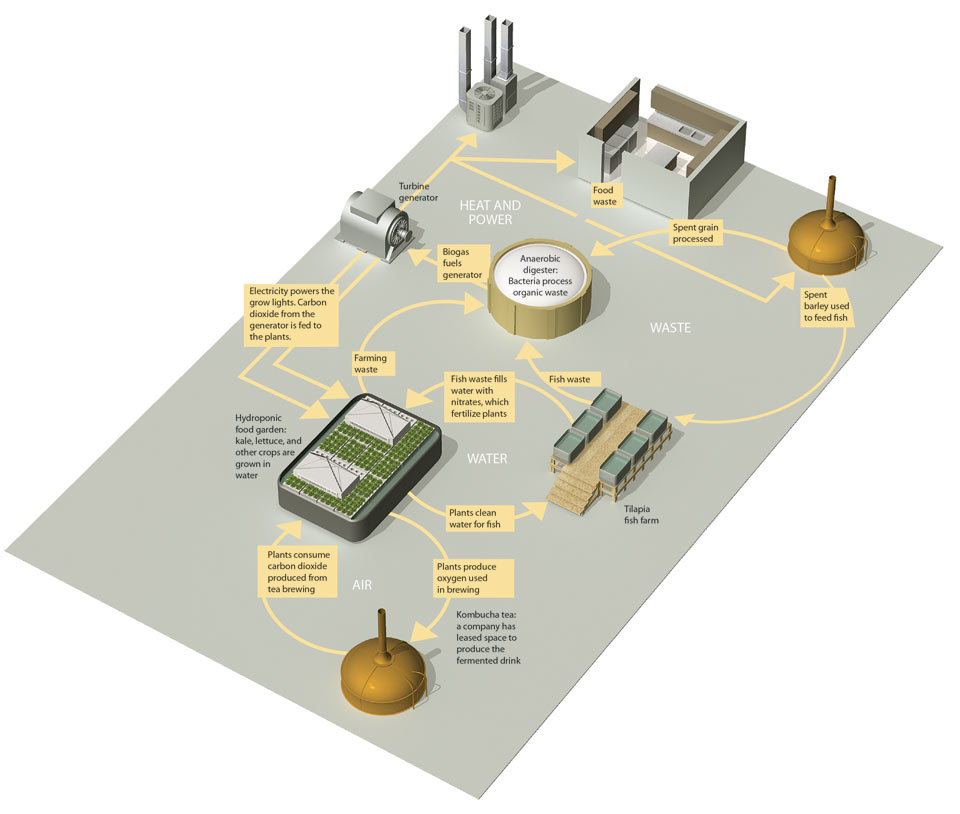

The Plant is a farm like no other, incorporating complementary food-production facilities such as a beer brewery and kombucha tea maker. Every component of the facility uses waste that the other components produce, creating a closed system that provides its own power, uses all of its own waste, and produces a variety of food and beverages for consumers, restaurants, and markets.

Power

The anaerobic digester uses bacteria to turn organic waste into gas used to power the turbine generator, which provides power and heat for the building. In addition, hydroponic garden plants will consume carbon dioxide that the generator produces. The digestate byproduct of anaerobic digestion is, in turn, used as high-nitrogen fertilizer for outdoor growing operations.

Food/Beverage Production

A beer brewer and kombucha tea maker are currently building facilities at The Plant. The spent grain from the beer brewing process will feed the fish and provide fuel for the anaerobic digester. Oxygen that the garden crops produce will be used in brewing tea, and the gardens will consume carbon dioxide produced during the brewing process. Waste from a commercial kitchen at the facility will also go to the anaerobic digester.

Farming

The hydroponic gardens produce crops such as kale, lettuce, basil, and watercress, and mushrooms will be grown in spent grain from the brewery. The tilapia fish farm will grow to eventually allow sale of mature fish on the market. Fish waste provides fertilizer for the crops while the garden cleans the water in tanks housing the fish. Additional fish and garden waste provide organic fuel for the anaerobic digester.

RYAN MARX AND PHIL GEIB/TRIBUNE

More Online

The Plant: plantchicago.com