Photos: David Ettinger

From their home in Bagasara, India, Piyush Desai (M.S. EE ’04, Ph.D. ’09) grew up helping his father fix household items, ranging from motors to gramophones to old radios that operated using valves and tubes.

“My dad had a dream of being an engineer, but he had to drop out of school to work in my grandfather’s shop and wasn’t able to achieve that dream. By working with him, engineering became my choice unconsciously,” says Desai.

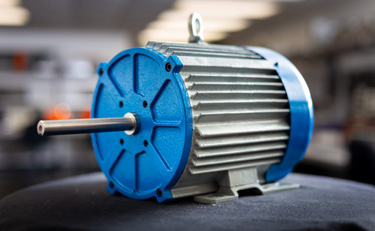

Having been raised to view natural resources as sacred, Desai realized the immense energy-saving potential by modernizing motors and drives.

“Motors are both the entrance and exit of the energy food chain,” says Desai. “Almost 95 percent of electricity is generated by an electric motor, and almost 50 percent of that electricity is consumed by an electric motor.”

He carried this fundamental belief with him in his first semester as a master’s student at Illinois Institute of Technology in 2002. Having left both a decade-long career and his wife and young daughter in India, Desai was focused entirely on reaching a level of success in the program to make the sacrifices worth it. He immediately began searching for a research project that would offer a real-world impact. But he didn’t confine himself to the most popular motors of the time.

“I believe not just in invention, but in retro-invention,” says Desai. “I firmly believe that we can always find ideas that were ahead of their time.”

He came across the switched reluctance motor (SRM), a nearly 200-year-old design whose reliance on then-futuristic electronic sensors and computing power had caused others to dismiss it for decades.

But in the early 2000s, with computing power becoming more powerful, affordable, and accessible every year, Desai believed that the SRM’s time had come.

At that time, compared to induction motors that had been the focus of decades of research and development, SRMs were inefficient, noisy, and weak. The maturity of the technology had a long way to go, but Desai saw the benefits of SRMs.

“[The SRM] is inherently cost-effective, it’s highly reliable, and it’s fault-tolerant. With other motors, if something goes wrong the motor shuts down. With SRMs, you can limp home with reduced performance and discomfort, but at least if it was in your car, you can drive it slowly and go home or get to the nearest repair shop,” says Desai.

This fault-tolerance had kept SRMs in use in a few applications where reliability was mission-critical, such as nuclear power plants. Desai felt that even if he only solved one of the SRM’s problems, that would be enough to give them the edge over other motors in some markets.

He began learning everything he could about SRMs.

Longstanding SRM designs used four rotor poles, protrusions from the central rotating shaft that make the motor spin by rotating to align with a surrounding magnetic field. It was conventionally believed that increasing the number of rotor poles would decrease performance.

Desai was convinced this was wrong and set out to prove it.

He became a fixture in the motors laboratory in the basement of Siegel Hall, showing up early most mornings and working until after dark. He chipped away at the problem, prototyping and testing motor components and learning sophisticated numerical modeling, which allows for virtual prototyping, a tool he still considers central to his success.

“I really want to break my head on simulations. I put the majority of my efforts into perfecting the art of simulating to a point where simulation is not a rough approximation, but it’s a pretty darn bullseye,” he says.

Within two years, Desai was filing for a patent for a high rotor pole SRM. Not only had he managed to make it run, but he had also increased the motor’s efficiency and power.

“Technologists can become stagnant,” says Nigel Schofield, a professor at the University of Huddersfield in the United Kingdom who collaborated with Desai during this time. “People just copy and iterate and tweak, and then suddenly, somebody like Piyush will come along and say, ‘I want to do it totally different.’ It started people thinking about doing things differently, which opened up the field and spurred a lot of other ideas.”

By 2013, he was focused on building his own consulting firm. Then his patent caught the attention of Silicon Valley entrepreneurs who reached out to see if Desai would be interested in building a startup together centered on SRMs.

“I believe not just in invention, but in retro-invention,”

“I firmly believe that we can always find ideas that were ahead of their time.”

—Piyush Desai

Desai knew this was his big break.

They co-founded a company, now called Turntide Technologies, that considers SRMs as revolutionary to the motor market as LEDs were to lightbulbs.

While other electric motors tend to only have high efficiency under narrow running conditions, Turntide has achieved high efficiency across the board in SRMs. In 2019 the National Renewable Energy Laboratory found up to 71 percent energy savings in HVAC systems that were switched to Turntide SRMs.

As it turns its sights on the exploding electric vehicle market, Turntide’s motors have attracted investors such as Amazon, BMW, and Bill Gates. In 2021 the company received $225 million in financing, bringing its total funding to $400 million.

Turntide has installed more than 5,000 SRMs and grown to more than 500 employees. Desai’s mission is to reduce the energy consumption of electric motors worldwide by replacing them with SRMs.

“It’s fortunate to be in a position where you can live your values entirely. I’m not selling sugary candy while prohibiting my kids from eating it,” says Desai. “I can live just one life.”●